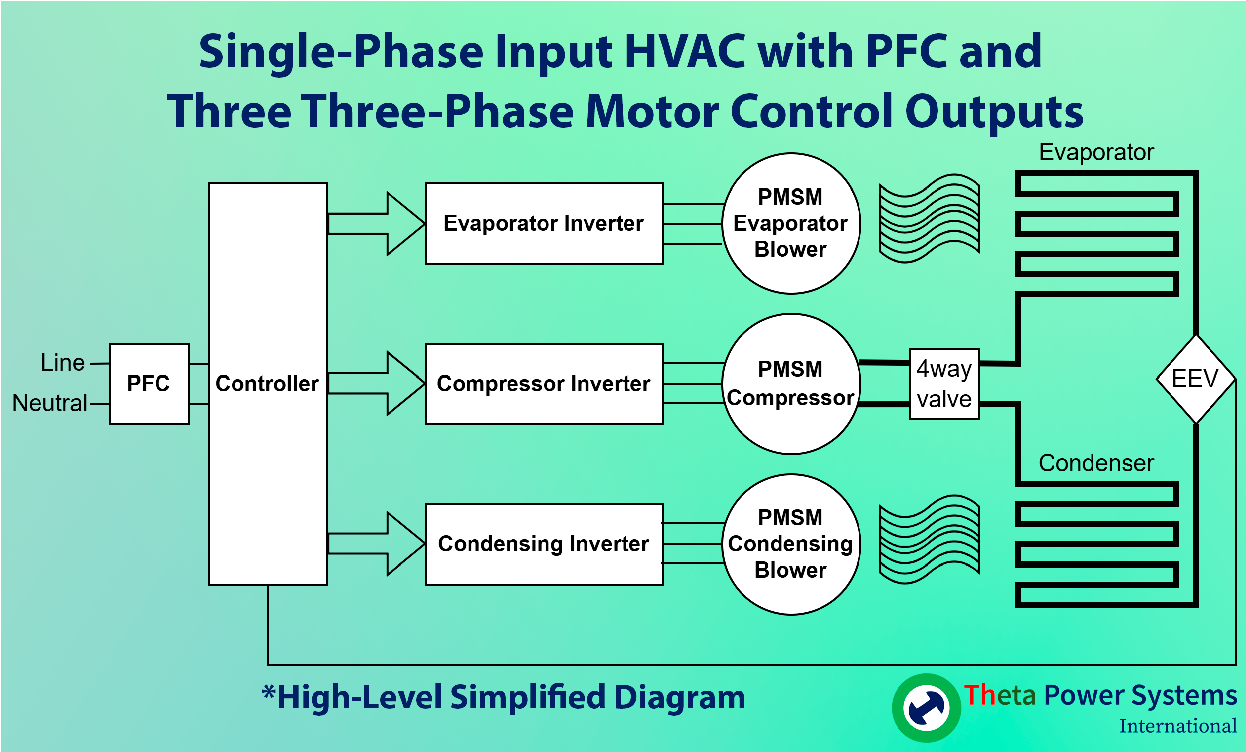

Single-Phase Input HVAC with PFC and Three Three-Phase Motor Control Outputs

Air Conditioners: Essential for Comfort and Efficiency

Air conditioners have evolved from a luxury to a necessity, as everyone now expects to live and work in stable and comfortable temperatures. With the escalating effects of climate change, the demand for high-performance, efficient, and cost-effective equipment has become more critical. Moreover, air conditioning technology is increasingly being applied in areas like food refrigeration, industrial processes, and even battery refrigeration for electric vehicles.

Incorporating Variable Speed Technology

Variable speed technology is commonly used in evaporators and compressors to enhance air conditioner performance and energy efficiency. However, variable speed condenser fans are less common. Integrating these with an Electronic Expansion Valve enables the system to excel in noise reduction, user comfort, refrigeration performance, energy efficiency and Maintaining precise temperature thresholds in both cooling and heating modes (4 way valve).

Noise Reduction

Noise levels are a primary concern for consumers, especially if the sound is loud or unpleasant. Variable speed motors generally operate quieter across all speeds, particularly because they can run slower. Additionally, three-phase motor inverter drives allow different motor control techniques. Our proprietary Direct Torque and Flux Control techniques, combined with Theta's patent-pending Noise and Vibration Reduction Algorithm, address not only software improvements but also mechanical vibration challenges. ( Click here to understand more)

Enhanced User Comfort

User comfort extends beyond noise to include temperature and humidity stability, minimizing significant temperature fluctuations that are noticeable to customers. By varying the speeds of the evaporator fan, compressor, and condenser fan, our systems optimize heat dissipation when needed, improving temperature, humidity control and the efficiency of the refrigeration cycle.

Energy Efficiency

From a temperature control perspective, there is no need for all three motors to operate at high speed continuously. While it's common to see condenser fans running at full and fixed speed, operating them at reduced speeds during lower cooling demands saves energy. Additionally, implementing low ambient head pressure control ensures consistent performance and prevents issues such as freezing or reduced heating capability in heat pumps. Moreover , running at lower speeds reduces mechanical wear, prolonging the lifespan of fan components.

Control and Algorithms

Variable speed motors in all components of the refrigeration system expand the scope of control algorithms. This capability allows the system to do more than just manage efficient refrigeration cycles and smooth temperature transitions; it also supports complex protection and recovery algorithms to prevent ice formation and other issues such as noise and vibration.

At Theta, we do more than just meet requirements; we collaborate with your team from concept to product approval to develop innovative, cost-effective solutions. In this project, we successfully utilized a single microcontroller to manage three three-phase motors, showcasing our dedication to both cost efficiency and innovation.

Get in Touch

Contact us today to discover how we can tailor solutions that meet your specific needs, preparing your business for the future.

Contact us Return to Home